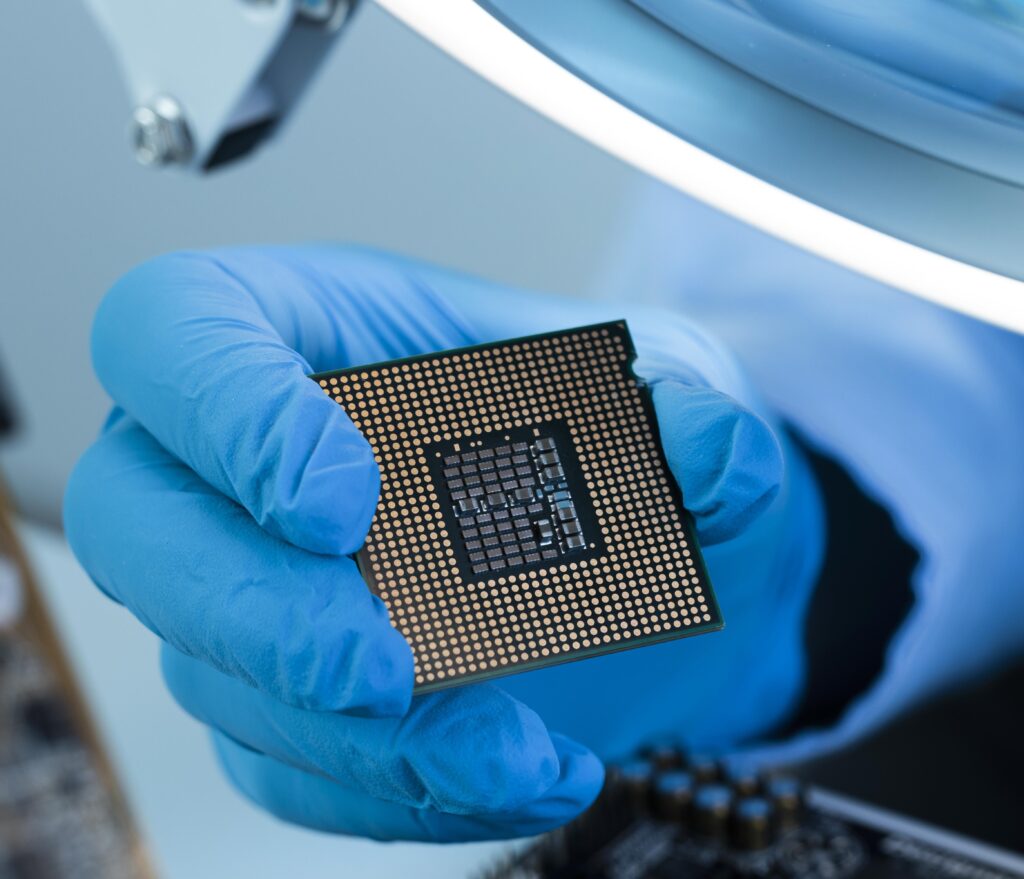

Powering the Future with Semiconductor Innovation

Driving Operational Excellence Through Agile Semiconductor Transformation

Key Benefits

- Accelerate tape-out cycles with agile design and validation.

- Improve collaboration across design, fab, and test teams.

- Optimize fab utilization and reduce downtime.

- Enhance product quality through iterative feedback.

- Speed up delivery to meet market demands.

- Foster innovation with continuous improvement culture.

Our Transformation Process

A structured, end-to-end approach to enable agile transformation and deliver measurable, sustainable outcomes.

Assessment & Discovery

Analyze your current design ecosystem to uncover performance gaps and optimization opportunities

Key Activities:

- Team interviews

- EDA flow audit

- Yield analysis

- Readiness check

Strategy & Roadmap

Craft a transformation plan tailored to your design goals, market timelines, and technology stack.

Key Activities:

- Vision alignment

- Team setup

- KPI definition

- Change planning

Implementation & Training

Introduce agile practices, streamline tools, and align design processes for improved delivery.

Key Activities:

- Workshops & training

- Flow redesign

- Toolchain tuning

- Cross-team sync

Coaching & Refinement

Embed new habits, solve bottlenecks, and continuously enhance engineering output.

Key Activities:

- Agile coaching

- Debug mentoring

- Metric refinement

- Issue resolution

Delivering Tangible Business Outcomes for the Semiconductor Industry

Our end-to-end semiconductor consulting and engineering services are designed to enhance performance, agility, and innovation across your value chain—from chip design to production.

Faster Time to Market

Reduce IC development and tape-out cycles by streamlining design, prototyping, and manufacturing stages with agile methodologies.

Stronger Team Performance

Enable better collaboration between cross-functional teams—EDA engineers, layout teams, and fabrication units—through structured communication and agile workflows.

Greater Business Agility

Respond faster to changes in process nodes, market demand, and technology trends with flexible operations and modular engineering strategies.

Improved Product Quality

Implement robust DFM (design for manufacturing), real-time defect tracking, and iterative testing to ensure higher silicon yield and lower rework rates.

Smarter Risk Management

Mitigate risks like silicon failures, EDA tool mismatches, and supply chain delays through early diagnostics and scenario-based planning.

Optimized Resource Utilization

Maximize productivity of fabrication lines, engineering resources, and EDA licenses through efficient allocation and automation strategies.

Clear Portfolio Visibility

Achieve real-time visibility across the chip lifecycle—from RTL to tape-out—with integrated dashboards and predictive analytics.

Cultural Transformation

Foster an innovation-driven within engineering and production teams to support faster scaling and sustainable growth.

Typical Client Results

35-50%

Faster Time to Market

20-40%

Increase in Productivity

30-60%

Defect Reduction

25-45%

Higher Employee Engagement

What Our Graduates Say

Hear from professionals who have completed our Agile Transformation Coach certification.

The transformation process exceeded our expectations. Not only did we see immediate improvements in delivery speed, but the cultural shift has been truly remarkable. Our teams are now empowered, engaged, and consistently

delivering value.

Sarah Johnson

CTO, Global Financial Services

What impressed us most was how the consultants tailored their approach to our specific needs. They didn’t just implement a

cookie-cutter solution, but took the time to understand our unique challenges and address them appropriately..

Michael Chen

VP of Product Development, Healthcare Solutions Inc.

The ROI on our agile transformation has been substantial. Beyond the metrics improvements, we’ve seen a fundamental change in how our teams approach problems and collaborate across the organization.

Rachel Williams

Director of Technology, Retail Innovations Group

Frequently Asked Questions

Find answers to some of the most common questions about our agile transformation consulting services.

We incorporate global best practices such as Design for Test (DFT), Design for Manufacturability (DFM), and Statistical Process Control (SPC). Quality is reinforced with continuous verification, automated test coverage, silicon debug processes, and compliance with standards like ISO 9001, ISO 26262 (automotive), and JEDEC reliability protocols—ensuring high yield and reduced risk of post-silicon failures.

Unlike traditional consulting firms, our model blends deep technical expertise in chip design, manufacturing, and toolchain optimization with agile business transformation. We don’t just advise—we embed with your teams, co-own outcomes, and tailor strategies that are scalable, measurable, and execution-focused. With a proven track record across ASIC, SoC, memory, and analog domains, we enable semiconductor companies to build a sustainable competitive edge.

Connect With Us

Take the first step toward greater agility, faster delivery, and improved outcomes.